There is no universally accepted, standard format for tech packs. It is no wonder that there is so much confusion around what needs to be included in one. I’ve seen anything from a two-page overview to a 20+ page industrial process document called a tech pack.

Within that spectrum, I think there are really two types of documents: design specs and tech packs. The line between the two is fuzzy. They are both useful, but they serve different purposes. If you send them to a factory and request a sample, they are not going to get you the same results. Let’s break down the differences and when you might use one over the other.

Design Spec

At first glance, a design spec has a lot of the same elements as a tech pack. The flat sketch is there with callouts or maybe reference photos. Fabrics and colors are noted. The brand name and collection or season is at the top of the page. It might even include some sample measurements.

A design spec focuses on the design itself. The document shows what the style is. It is a wonderful way for designers to communicate their vision for the style to a technical design team. The information here might end up on line sheets, product descriptions, as well as within the full tech pack.

Tech Pack

A tech pack starts with some of the same elements as a design spec, but it is much more in depth.

A thorough tech pack doesn’t leave any detail to the imagination. It covers details like materials, machine types, sewing order, label and trim placements, Pantone TCX or vendor color sku codes, and full graded specs, and so much more. Tech packs are comprehensive documents! (My tech packs are typically 12-20 pages long depending on the complexity of the style.)

A tech pack is the document you want to send to a factory when requesting a sample. It is useful for you as the designer in many ways as well!

The main difference between a design spec and tech pack

While a design spec outlines what the design IS, a tech pack outlines how the design is MADE. This is the key distinction.

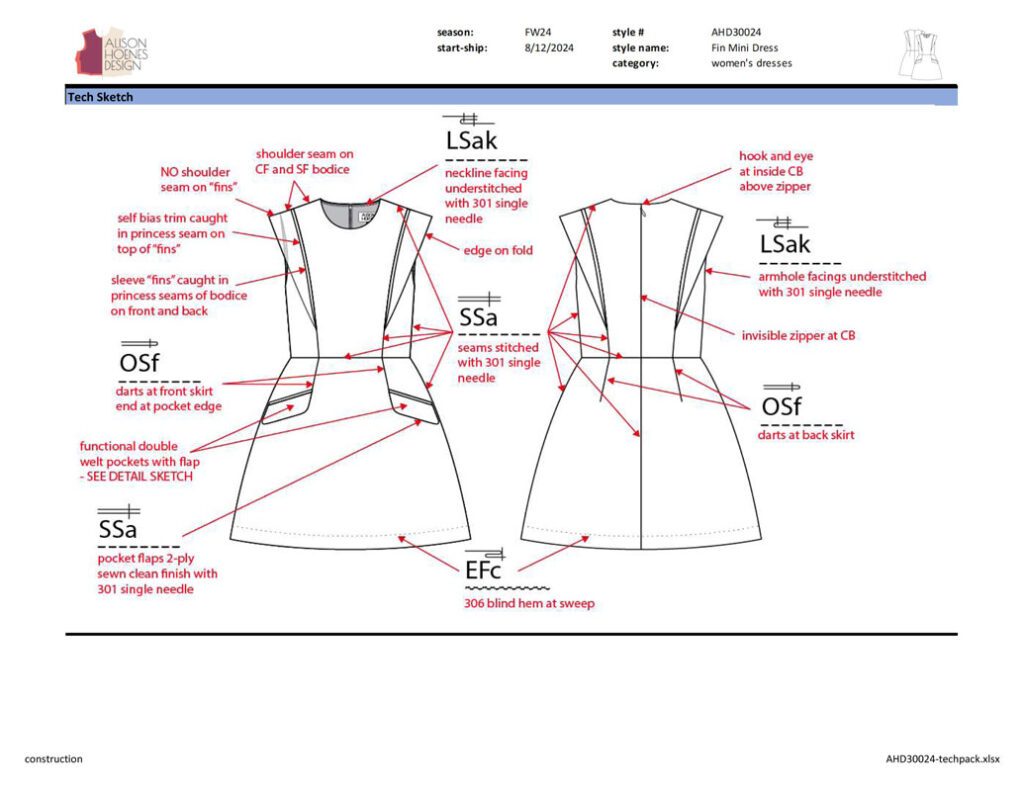

Take a look at what is called out in each document.

The design spec calls out things like:

- skirt and bodice are lined

- invisible zipper at center back

- double welt pockets with flap

The tech pack calls out things like:

- EFc 306 blind hem at sweep

- LSak armhole facings understitched with 301 single needle

- SSa seams stitched with 301 single needle

The design spec calls out features while the tech pack calls out construction using industry seam and stitch codes. What a factory or samplemaker needs is these construction specifications. If you provide them a design spec, they have to guess what finishes you want, how you want the inside to look, and exactly what “navy” color you are thinking of. Their guess may not be what you have in mind.

If you are unhappy with the quality or number of sample rounds you’ve gone through with your factory, take a look at the document you sent them. Does what you have look more like a design spec than a tech pack? If so, start there and work with your technical designer to expand the “what” of your design spec into the “how” of a full tech pack. You’ll see much better sample results.