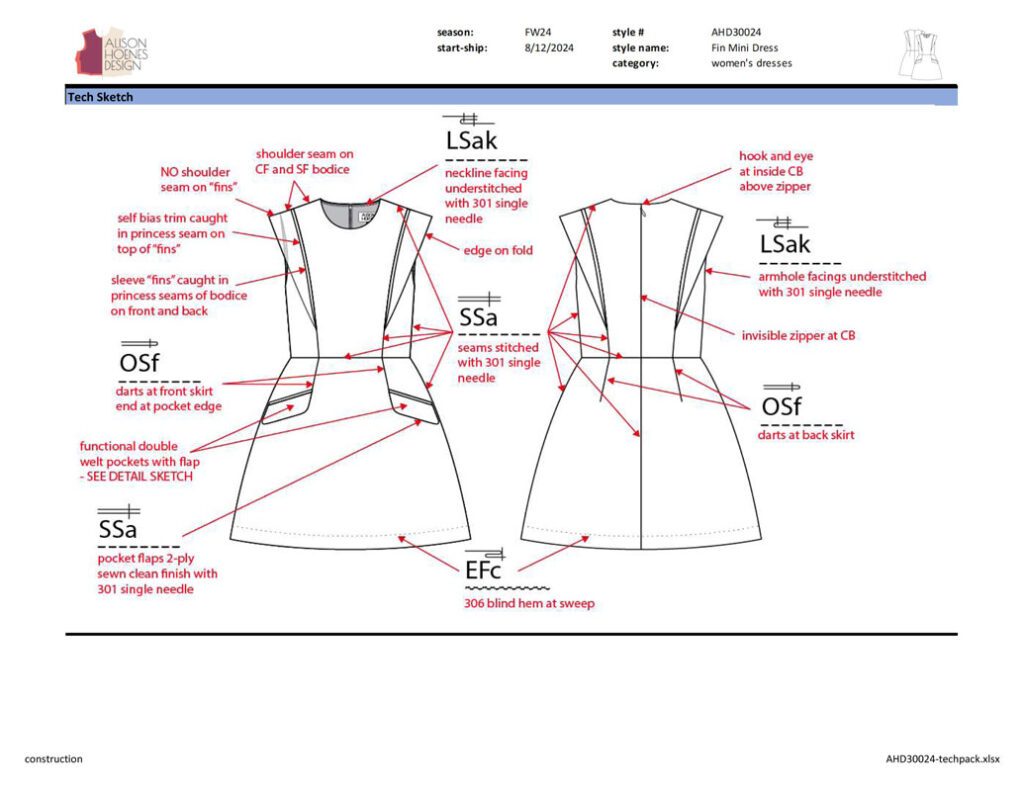

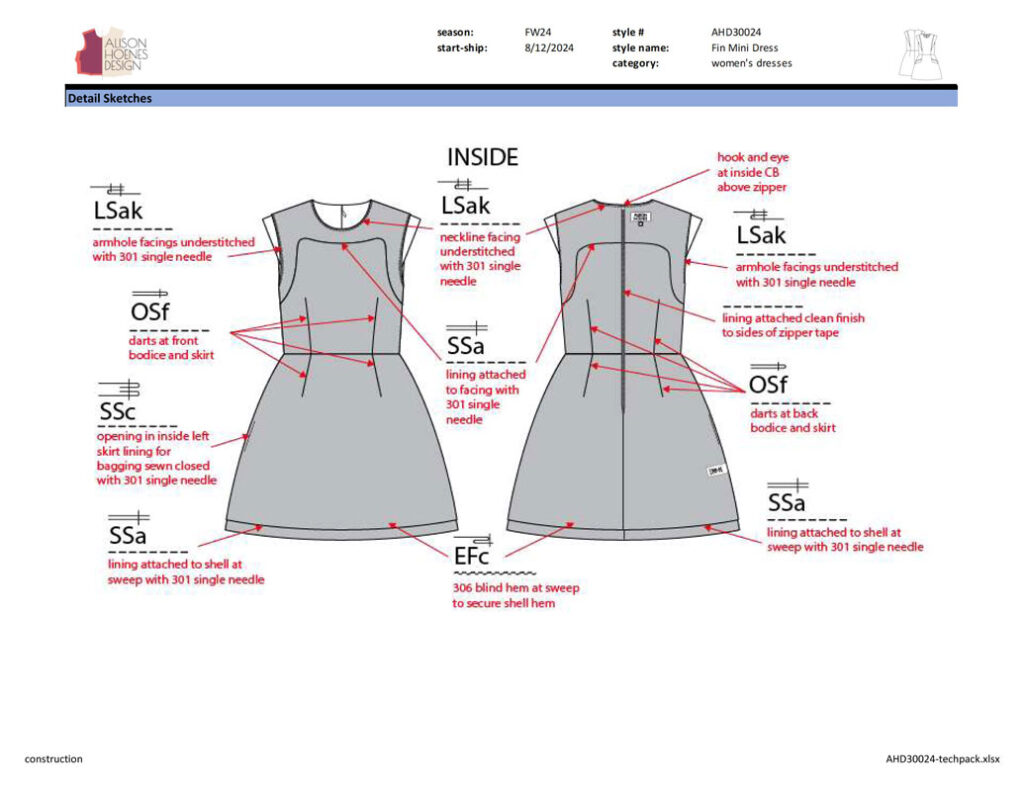

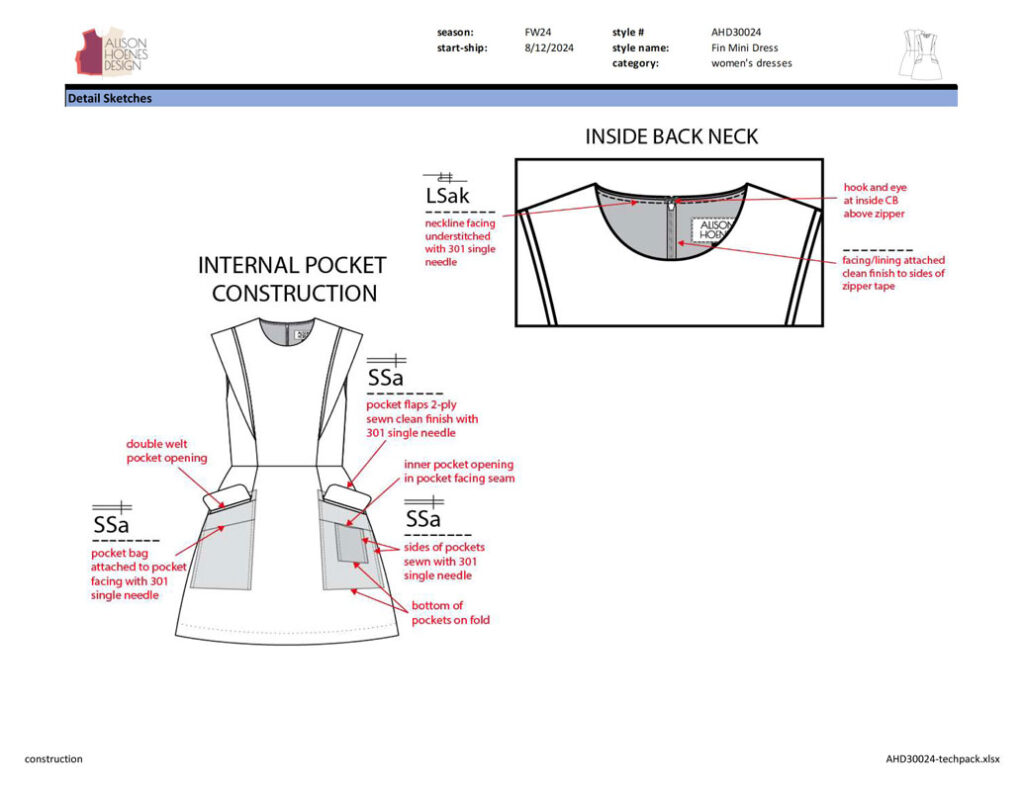

The technical section of a tech pack communicates how the garment is constructed. It will always include a tech sketch which is the flat sketch from the cover page with seam, stitch, and detail callouts. Some details will have expanded close-up sketches or alternate views such as the sides or inside showing how those details should be constructed.

The sketches will show how each edge is joined (what seam type) and with what technique (the stitch type). To further clarify the construction, I always use ASTM/ISO codes and diagrams within my tech callouts as most factories are familiar with these standards.

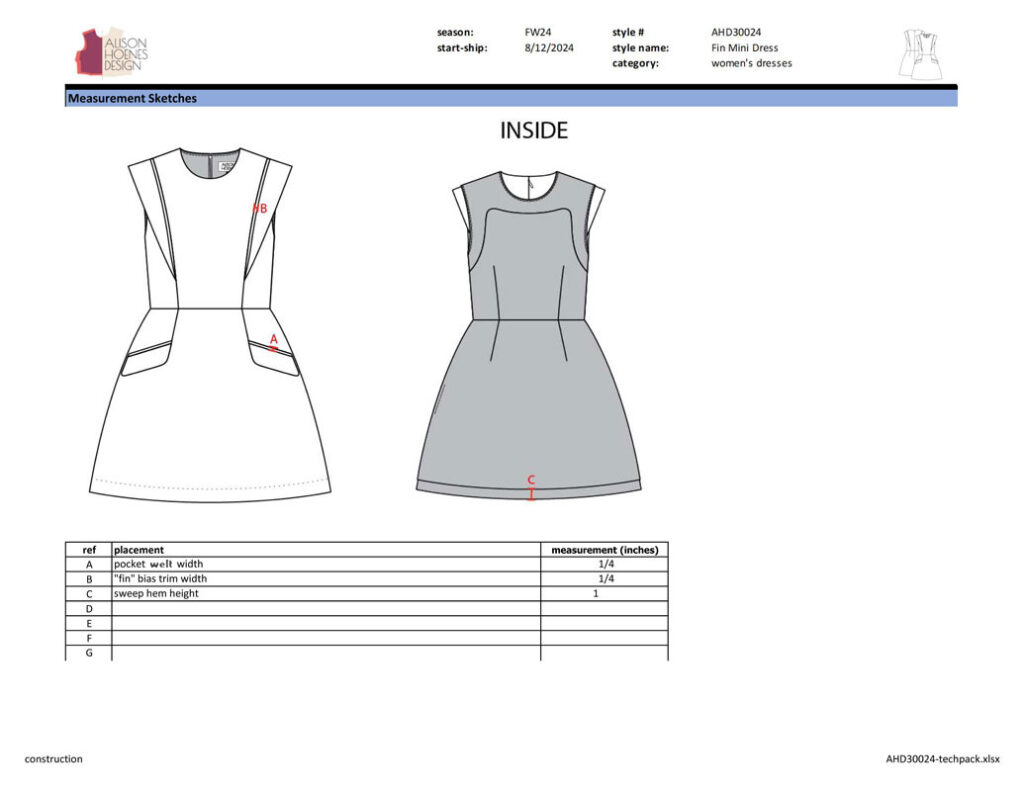

Within the construction section, there is also a page for trim and hem measurements. The graded measurements will come in a later section, but this page calls out measurements that don’t change with size. You’ll see things like hem heights, trim widths, and topstitching spacing.

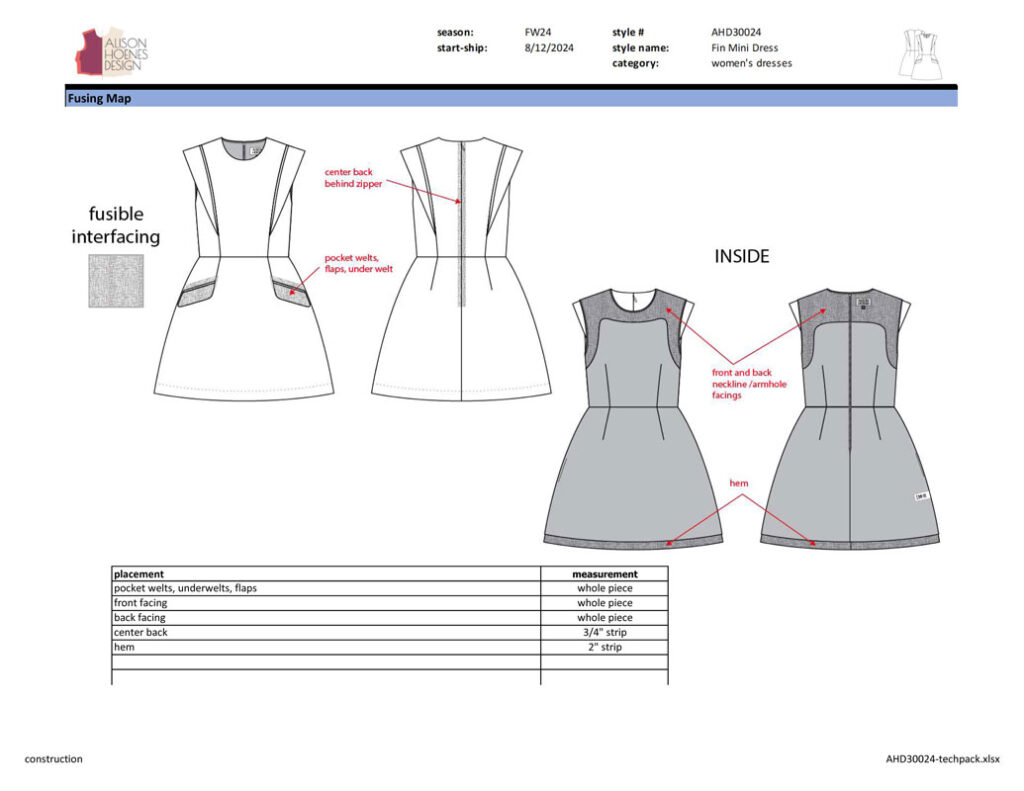

If the garment has internal structuring like boning or interfacing, that is illustrated on the fusing map page. Note, fusing pieces should be included in the pattern as well. Whether the fusible pieces are block fused or only partially fused to stabilize certain areas, the placement is called out here.

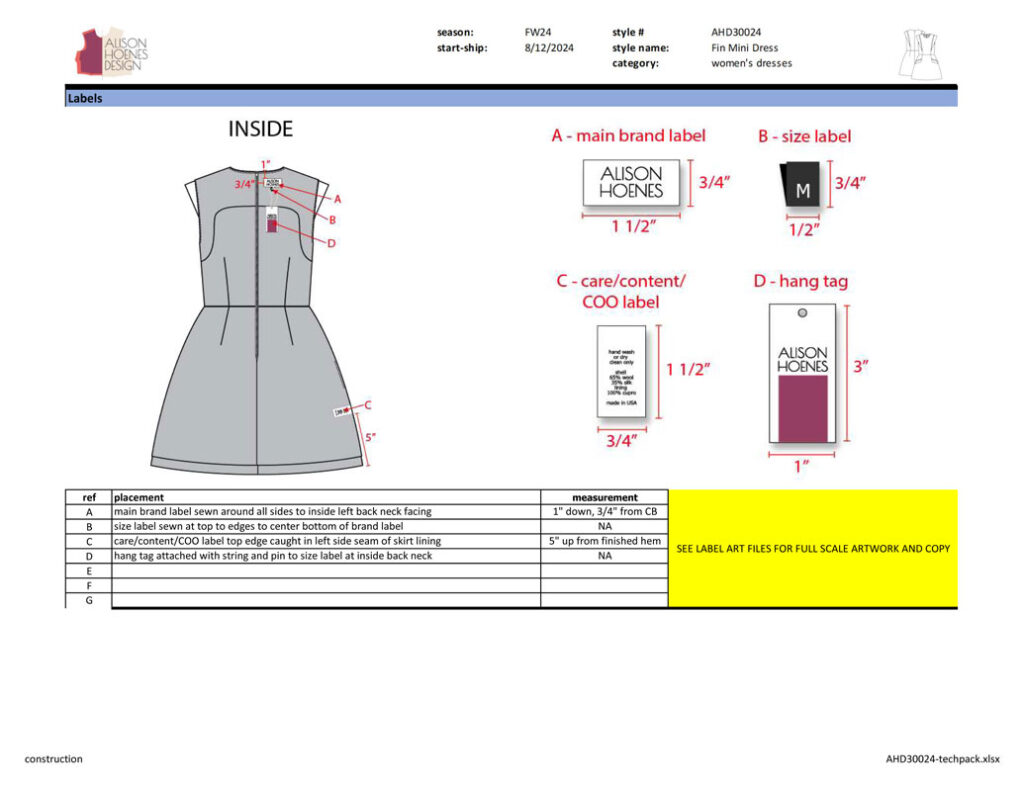

Another page in the technical construction section specifies what labels and hang tags are used for the garment. It will show the placement of the label on the garment as well as a mock-up of the labels showing their dimensions.

These aren’t the artwork files that the label printer will use, just mockups so the factory can select the right label from your inventory and sew it in the right place on the garment.

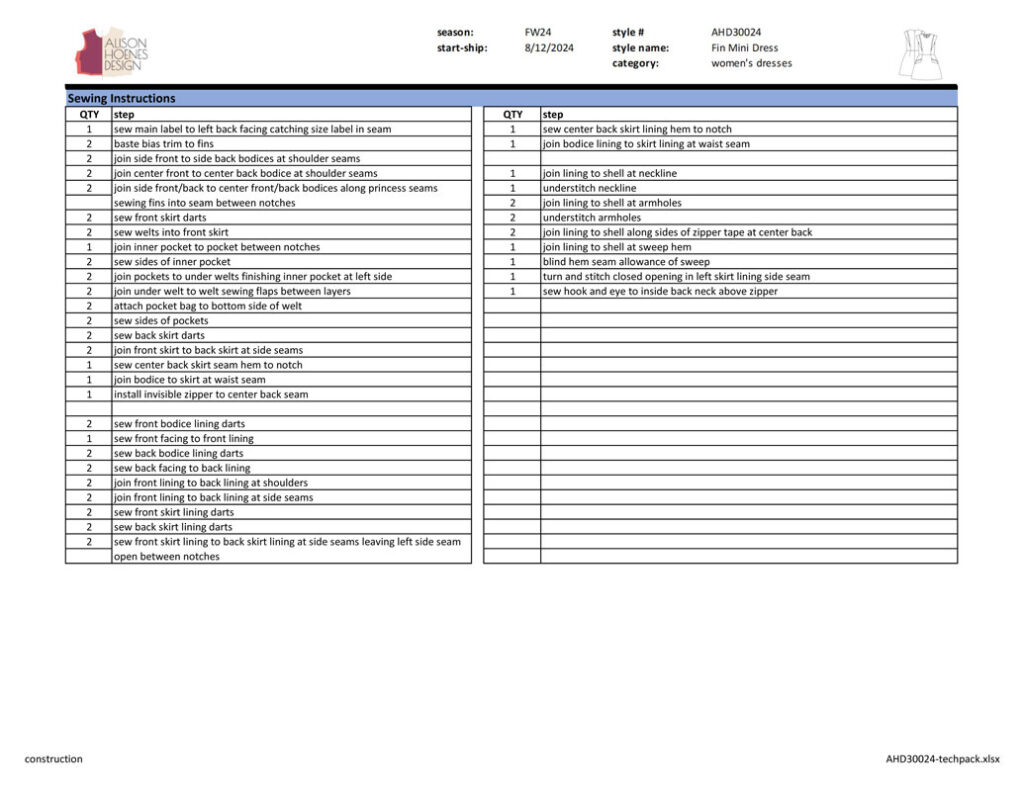

The final page in the technical section is the sewing order of operations. This section lists out each step of the sewing process to make the garment. The order of operations indicates how you want the garment finished. The order in which the garment is sewn affects the price, look, and quality. It is best to have your patternmaker, samplemaker, or factory write the order of operations as they can advise what order is appropriate for your product and price point and their workflow.

The technical sketch and construction section helps you the designer in several ways. Knowing what seam and stitch types are used in the style will help you when interviewing or deciding on a factory to make the style. Not every factory has every type of machine. When you meet with a factory, you can bring your tech pack and show them just what is required to produce your product. Instead of guessing, you and the factory can determine upfront if they have the necessary machinery.

When you receive a sample back from your factory, you can visually check it against the tech pack. Is it lined? Does it have double turn hems or single turn edge finishes? Did they use the right seams? Does the stitching look the same? Even if you don’t know how to sew, you can look at the tech sketch to confirm that all the design details and finishes you asked for are included in the final design.