There are a lot more numbers in fashion than the glamorous creative stereotype lets on. For a designer who’s not immersed in the numbers all day long, they can be confusing. Size charts, spec charts, and grade rules are all terms that are thrown around alot during development and pre-production. While they do sound (and sometimes look a bit) similar, their meanings are all distinct and each has a different use and purpose.

Size Charts

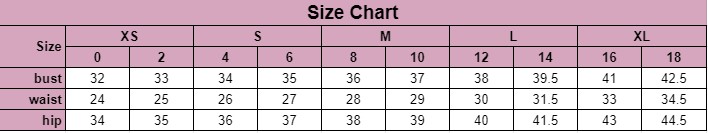

A size chart is the customer-facing numbers. This chart is what’s on your brand’s website so your customers will know what size to order.

What the numbers mean:

The numbers in a size chart are body measurements – not garment measurements. The size chart doesn’t give the measurements for any specific design or garment, but rather shows what general body measurements correspond to each size.

How to use a size chart:

The purpose of a size chart is for your customers to be able to know what size to order to best fit them. The customer will have to measure themselves and see which size is the closest match to their own body measurements. In addition to a size chart, you can make notes on individual product pages about fit and sizing of that specific design such as how fitted it is, how long the garment length or inseam is, or whether you recommend sizing up if a roomier fit is preferred.

Spec Chart

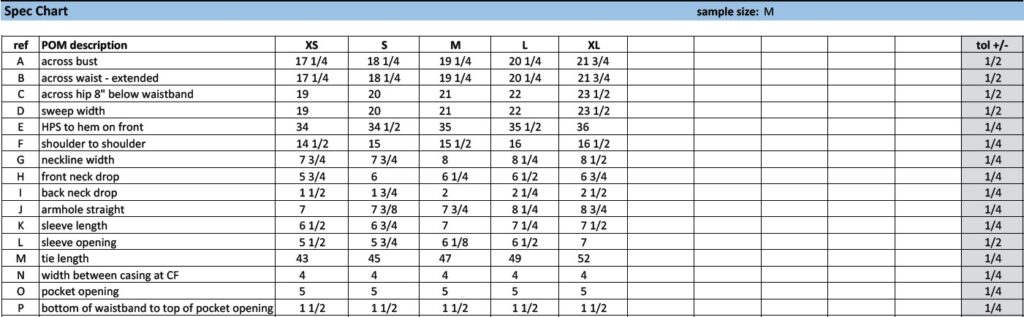

Spec Charts are for development, production, and quality control purposes. They are used internally and by your factory. The spec chart – also known as a spec sheet, graded spec, or garment POMs (points of measure) – are included as part of the tech pack for each garment.

What the numbers mean:

Spec chart measurements are garment measures. The spec chart describes where the measurement is taken and then lists what the measurement should be for each size in the size range for the style.

There is also a column for tolerances. Cutting, sewing, and the fabric itself has a margin of error and the numbers in the tolerance column show what is an acceptable variation in measurement for each point of measure. For example, if the tolerance is ½” and the spec says the bust should be 19 ¼” for a size M, any garment measuring between 18 ¾” and 19 ¾” is acceptable as a size M garment for that point of measure.

The spec chart measurements may also be closely related to the actual pattern measurements, though not always.

How to use a spec chart:

Spec charts are used for many things. During development, a spec chart can be used to request certain sample measurements from your patternmaker or factory. For example, you could request a certain sleeve length, skirt length, or waistband size by using a spec chart.

A spec chart is most often used for quality control during development, sampling, and production. The finished sample can be measured against the spec chart to make sure it falls within acceptable tolerances. If it doesn’t, you’ll want to troubleshoot why that is before you decide to make any changes during a fitting.

In production, the spec chart is used by you and your factory to quality check the finished garments. The tech pack – including the spec chart – is an informal contract of sorts between you and the factory that ensures you both understand what is expected and what is considered acceptable quality.

Need help creating your own spec charts?

Create graded spec charts in less than 15 minutes of time with just a measuring tape and sample garment – no math involved – with graded spec chart templates.

Grade Rule

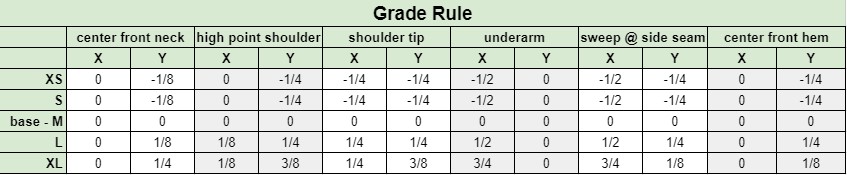

A grade rule is a technical set of numbers that your patternmaker or pattern grader uses to create other sizes from your base or sample size. You as the designer probably won’t ever need to use a grade rule yourself unless you are doing your own pattern grading. If you don’t have a grade rule for your brand, your patternmaker or grader will be able to help develop one for you based on your size chart or spec chart.

What the numbers mean:

The numbers in a grade rule can be described as amounts of movement. Each number indicates how much (and in which direction) a given point moves between two adjacent sizes. A grade rule is the collection of these movements for each point and size along the X and Y axes. Notice, the size M base size is ‘0’ all the way across the chart – this is because the size M is the base sample size in this case and so it is the reference size from which the other sizes move from.

These numbers are sometimes shown as cumulative away from the base size, but are often shown as movements from the previous adjacent size as in the example above.

Grade rules are not the same as spec charts. These numbers show between the sizes, not the finished sizes themselves. Spec charts can show how much a point of measure changes or grows between sizes by looking at the difference between the sizes, but only the grade rule will show the complete picture of where in the garment that growth happens.

How to use a grade rule:

A grade rule is used to grade your patterns from the base size into all the other sizes you will be offering in that style. If you have digital patterns, the ‘.rul’ file is where the CAD system stores the grade rules for your pattern. CAD patternmaking softwares include the ability to import or export grade rules as well. A grade rule can also be created in a regular spreadsheet like in the example above and used as a grading reference to make sure each style in your brand is sized consistently.

Marie

8:59 am August 21, 2023Hi Alison, I hope you are well, I know you from Heidi's group and some of her videos. I have a customer who wants to add a note on their website in the size guide to address the possible size difference/ tolerance due to fabric, but I am not sure how best to desribe it. Any ideas! Kind regards Marie McElheron

Fermery

1:26 pm September 18, 2024Well...The info was very mush helpful, had a laugh for a bit. Anyway, I'm new with the whole fashion thing. I thought it's a wake up and purchase and dip. Regards Fermery

Megan

9:08 am May 28, 2025Is those waist measurements in inches

Alison Hoenes

12:42 pm May 29, 2025Hi Megan, yes! I typically do my spec sheets in inches because the majority of my clients produce and sell in the USA. For brands that produce or sell in other countries, I create the spec in centimeters (or include both for easy reference no matter the region). On the full spec pages, I note what the unit of measure is. Your comment makes me realize that that note is cropped out on these examples!