This two-part blog post was originally published as a guest post on the KRSTN NDRSN blog. KRSTN NDRSN is a swimwear + intimates freelance design studio for purpose-driven fashion brands. The beautiful 3D renderings in these posts are done by Trudy Gardner on the KRSTN NDRSN team.

Drafting a good pattern requires knowledge of the fabric it will be made in. This is especially true when working with stretch materials like those used for swimwear and intimate apparel. The combination of fabric properties and the pattern shape create the finished garment’s fit. Your design depends on getting this combination right.

Planning your materials and intended fit are the first steps in creating a well-fitting pattern in stretch materials.

Select your materials ahead of time

You can’t draft the pattern for the fabric properties unless you know what those properties are. Before starting your pattern, you’ll want to know which fabric you will use for the style and understand the nuances of its behavior. A wide variety of materials fall into the stretch fabric category, and they can yield quite different results in a garment.

Most of the time, when it comes to swimwear and intimates at least, stretch fabrics will mean knit fabrics. Knit fabrics are inherently stretchy regardless of their fiber content due to their construction. Woven fabrics can also be stretchy if they contain a stretch fiber like spandex or elastane. These stretch fibers can be used in woven and knit fabrics to add additional stretch to the fabric and compression that will return the fabric to its original shape after being stretched.

The direction of stretch is another important fabric property to note. Knit fabrics inherently stretch in width (cross-grain). In the length direction (straight grain), they can range from no stretch to lots of stretch depending on the type of knit and fiber content. Fabrics that stretch in width and length are called 4-way stretch fabrics. Woven fabrics, if they have a stretch fiber, usually stretch in the width direction. Warp stretch fabrics are an exception that stretch in length only.

The fabric type and the amount of stretch in each direction will inform how you draft your pattern to get the look and fit you desire. The fabric will also determine what seams and stitch types are appropriate, and, thus, what seam allowances should be included in your pattern.

Be clear about the intended fit and function

Fit can be subjective, and there is more than one way to use stretch fabrics in a garment. Before you start drafting your pattern, you want to be clear about the intended look and fit for the style. How fitted is the style supposed to be? Who is the target customer for this garment? What activities will they be doing while wearing this garment? The more specific you can be about the target customer, their fit preferences, and the use cases for the garment, the easier it will be to draft a pattern that meets these needs.

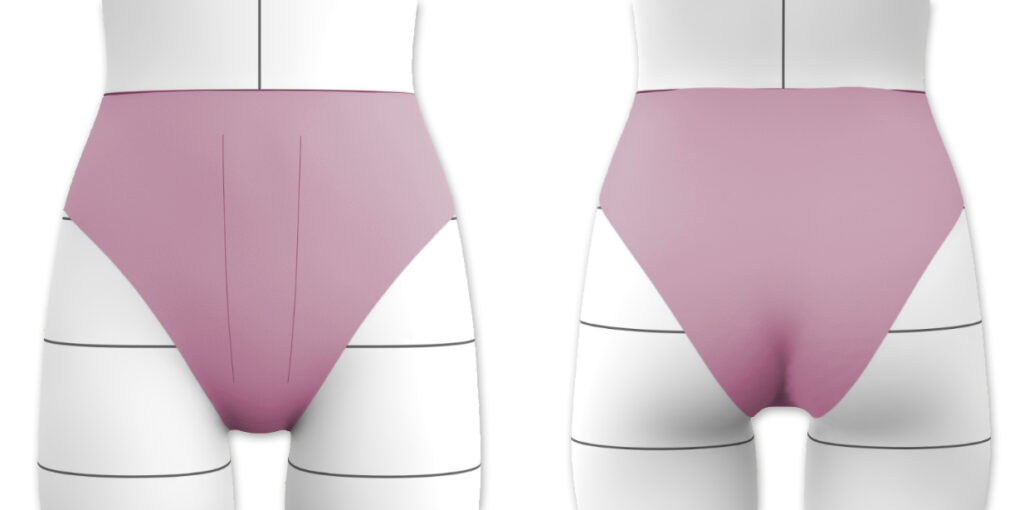

Stretch can serve several purposes in a garment. A little stretch can provide additional comfort and flexibility to an otherwise looser-fitting garment. In this case, the fit of the garment is not really reliant on the fabric stretch, and the pattern might look fairly similar to that of a non-stretch style. A lot of stretch can greatly shape the fit and conform to the body’s curves in a tight-fitting garment. Lots of stretch can replace other contouring techniques like darts or contour seaming in a pattern. A clear vision for the design and fit will help you draft an appropriate pattern.

Understand where the garment and wearer need support

It is important to understand what part of a garment provides support – especially in high-stretch and compression garments like swimwear and intimates. These types of garments are very functional and sit close to the skin – making fit and comfort vital. Your pattern will need to account for these areas of support and include adequate structure to uphold them for the garment’s lifespan.

For a bra, the underband supports the garment and the wearer. In a corset, the waist provides the structure for the rest of the garment. In a tank top, the straps will hold the weight of the garment. These areas of support will need the most attention to detail in your pattern to make the garment functional and comfortable to wear.

Identify the relative stretch of different garment areas

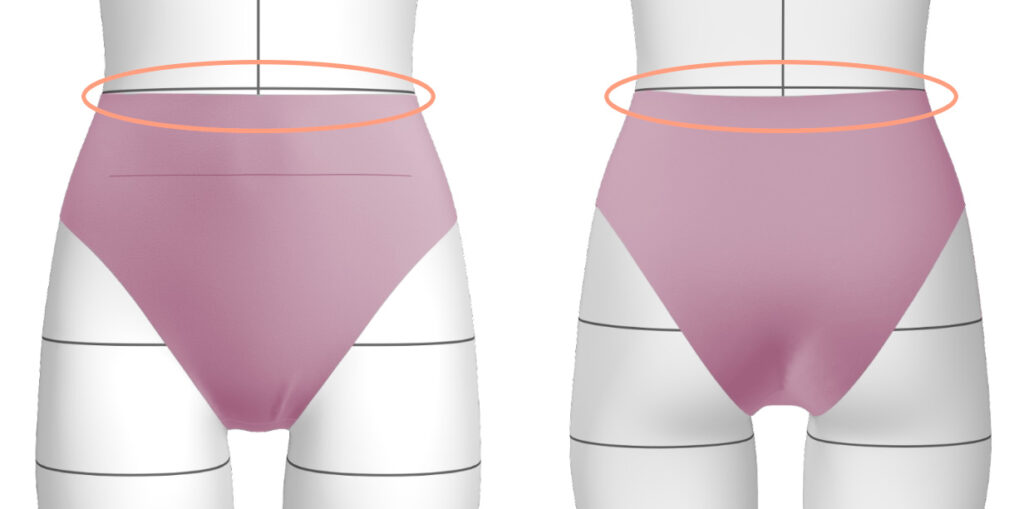

Even if the whole garment is made of the same stretch material, not every part of the garment will stretch equally when worn. This is a key aspect of drafting patterns for stretch fabrics that I don’t see talked about very much. The areas of the garment that are the tightest-fitting and those that provide the most support will be stretched the most.

To illustrate this, think about a one-piece swimsuit. Let’s map how much stretch is being used in each area. The torso will be stretched a lot in width as it wraps around the body on all sides. The torso will also experience vertical stretch from the shoulder to the crotch – but not necessarily evenly. The center will be stretched more as it extends from the shoulder to the crotch while the side seam doesn’t have as much vertical pull on its top and bottom sides. The straps experience the vertical stretch from the shoulder through to the crotch, but they aren’t being stretched at all in the horizontal direction.

What does this unequal stretch mean for your pattern? It means the areas that experience the most stretch will be more “squished” on your pattern than those that experience less stretch. Another way to put this is that the areas with high stretch will have negative ease in the pattern, but those with low or no stretch might have zero or even positive ease. You can see why drafting for stretch materials isn’t as simple as creating a pattern and applying the same stretch factor to the whole thing.

Planning out your design with the materials you will use and the fit you are intending gives you the information and understanding you need to draft a well-fitting pattern in stretch materials. Once you’ve done this planning, it is time to start creating the pattern itself.